Ever wondered what was involved in the beer brewing process?

Here’s a quick overview!

An overview of the beer brewing process

Let’s take a step by step look at the beer brewing process. The diagram below gives an overview of one such process, but you’ll find different brewers ad lib to the theme:

Milling

The first step in the brewing process is the milling of the whole malt grains to break the seed open. The result of this process is the grist.

Mashing

This grist is mixed with hot water to form a mash. The mash is left at a temperature of about 65°C for up to an hour during which the enzymes that were developed in the malting process break down the starches into fermentable sugars.

Lautering

The sweet mash is drained leaving behind the spent grains and the liquid, now called wort, is moved to the kettle.

Boiling

The wort is boiled and hops are added. The insoluble alpha acids in the hops isomerise, producing the bitterness in the beer.

Whirlpool

The now hopped wort is transferred to a whirlpool which separates the hop residue and excess proteins, known as trub, before the being rapidly cooled on its way to the fermenter.

Fermentation / Conditioning

Yeast is added to the wort, which metabolises the sugar and produces alcohol, carbon dioxide and a range of compounds that add to beer’s its flavours. Following fermentation a maturation process takes place in which the beer conditions and the flavours develop.

Packaging

Depending on the brewery and beer style, the beer can go through a variety of processes on its way through the packaging line including filtration and pasteurisation before it is bottled, kegged or canned.

Traditional methods combined with modern process control equipment

It is common for modern breweries to use traditional methods and equipment augmented by the use and integration of modern process control equipment. This generally ensures a consistently high quality production.

Craft brewing plants are usually equipped with electronic process controllers, which help to ensure that the same process parameters are applied batch after batch, therefore maintaining the consistent high quality of beer produced.

Another example of a beer brewing process

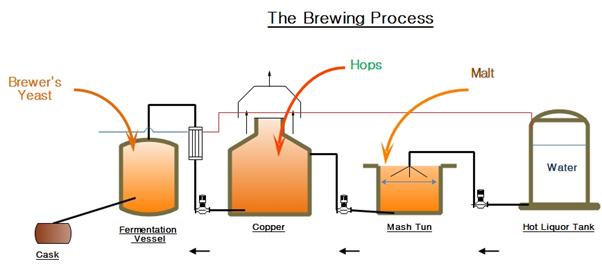

The beer brewing process diagram above flows from right to left.

- Water is heated in the Hot Liquor Tank and is mixed with the malt as it goes into the Mash Tun, where it is held for a while; the starch in the grain is converted to sugar by an enzyme called amylase which is naturally present in the malted grain.

- The resulting sugar rich wort is then pumped into a large boiling vessel known as the Copper. The wort is brought to the boil as the hops are added at different stages to give the distinctive flavours and bitterness of the beer.

- As prolonged temperature tends to weaken the bitter flavouring characteristic of a hop, it is important to transfer the wort from the copper into the fermentation vessel at a cooler temperature, this is done by pumping the hopped wort through a heat exchanger, which cools the wort and in turn heats up fresh water which flows into the Hot Liquor Tank, so preserving energy.

- Once the hopped wort is in the fermentation vessel, brewer’s yeast is added which converts the sugar in the wort into alcohol. After a period of time the resultant solution is taken out of the fermentation vessel and put it into casks, because now it has become beer.

This is a general overview of the beer brewing process, and may differ.

Leave a Reply